一、Outline

ZDL-M-axis current monitoring device uses a high-performance microcontroller as the core control components constitute controller, using hollow toroid axis current sensors, monitoring axis current changes produced by hydro-generating unit shaft. Single-chip real-time monitoring of changes in the value of the current sensor axis, the axis current value and large scales linearly, after filtering, numerical conversion processing to confirm axis current exceeds the setting value, the output shaft of the current monitoring means two alarm signals. As a device using four seven-segment LED display unit, parameter tuning, real-time display clear and intuitive. Meanwhile, ZDL-M-axis current monitoring device can output shaft current (0 ~ 5A) corresponding to 4 ~ 20mA analog signal standards, to meet the measurement requirements of computer monitoring system.

二、Feature

■High performance microcontroller core control components, has good reliability;

■SCM can be intelligent processing value, two alarm contact output, alarm contact setting value can be any setting within the range, the use of flexible;

■Axis current sensor using a half ring structure, easy to install;

■Using LED as a man-machine interface, axis current parameter values and device status clear and intuitive;

二、The main technical performance

Measuring range: 0 ~ 5A Flow capacity: 100A

Accuracy: <1% Digital Display mode: LED display

Output signal: relay contact output 2 groups Contact form: DPDT

Contact capacity: 10A / AC230V 5A / DC30V (resistive load)

Analog output: 4 ~ 20mA Load Impedance: 500Ω

Working environment: Temperature 0 ~ 50 ℃ Humidity <95%

Dimensions: Panel-mount: width × height × depth = 160 × 80 × 250

Power: DC / AC220V / 50HZ Power: 20W

三、working principle

Surrounded by the current changes in the shaft axis current sensor real-time monitoring of the spindle, the change in the amount of transformed and isolation after the enlargement process into the microcontroller's analog sampling port, single-chip sample values for filtering, accurate results correspond with the spindle current conversion process digital value. Input Monitoring button on the controller for the two alarm AL1, AL2 alarm set value. LED display can show the details spindle current value. SCM on acquisition value respectively two alarm set value compared to determine the status of the alarm output. Monitoring controller output 4 ~ 20mA analog current 0 ~ 5A spindle linear correspondence. Monitoring Controller testing transformer for self-test axis current monitoring device.

四、Panel

Four LED digital display window: Display Parameters

ok, lim1, lim2 nature of light: the digital display indicates the current

Keypad: Sets the operating instrument parameters

五、Terminals

AC220V power for the device, the device power-up work;

■ 4 ~ 20mA output current axis current 0 ~ 5A corresponds with shielded cable;

■ A1, A2 and axis winding phase current sensors work, you should use shielded cable, diameter not less than 1.5mm2;

■ B1, B2 and axis winding current sensor test phase, you should use shielded cable diameter is not small and 1.5mm2;

■ AL1 alarm 1 contact output (SPDT);

■ AL2 alarm 2 contact output (SPDT);

■ GND for the device chassis ground terminal;

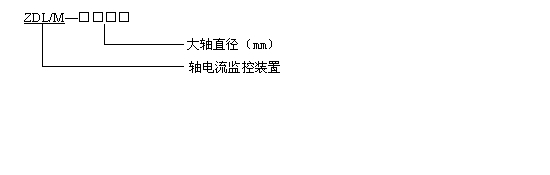

六、Selection Help